Our expertise in automated plating lines extends to the design and manufacture of Encapsulated Plating Systems for a range of plating processes. Systems are custom designed and can include integrated wastewater treatment plant.

NHE Encapsulated Plating Systems are the optimum solution where tank plating and selective brush plating are not suitable due to the component design, plating requirements, or production volumes.

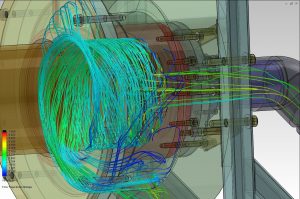

How Encapsulated Plating works

Bespoke tooling is used to isolate the area to be plated and through which plating solutions are passed.

We design customised tooling to accurately match the geometry of the selected area. Seals encapsulate the plating area, allowing the plating chemistry to flow over the plating area. Tooling design incorporates a custom designed anode and electro-deposition occurs when electric current is passed through the chemistry as it ‘flows’ over the component.

We work closely with sister company SIFCO ASC to ensure optimum plating performance and, where applicable, for the supply of plating chemistry.

In many cases multiple process steps – activation, rinse, plating – can be completed within the same tool and without removal of the part.

Encapsulated Plating can be applied to small and large scale components alike, and can be equally suitable for low to high quantities.

NHE Encapsulated Plating Systems provide:

- Fully automated production systems with fast cycle times for high throughput

- Higher speed plating compared with tank or selective brush plating

- Eliminating the need for complicated component masking

- Minimal operator intervention

- Optional robotic component handling

- Lower Capital Investment: encapsulated plating installations typically have a smaller footprint than tank plating lines and require less civil engineering to install

- Lower OPEX : improved energy efficiency due to significantly lower chemical usage

- Best-in-class Statistical Process Control – unmatched process consistency for the most demanding applications

- Highest standard of traceability – encapsulated plating is a ‘’one piece-flow” process. It can provide the full history of all critical process parameters for every single high value part produced. One-piece flow also limits the number of reworks in case of process deviation

In all cases, projects benefit from our commitment to designing and developing process plants and equipment with world class process quality.

Contact us now to discuss your specific requirements.