As pioneers in the application of vacuum distillation in 1986 VACUDEST were the first to make industrial wastewater reusable.

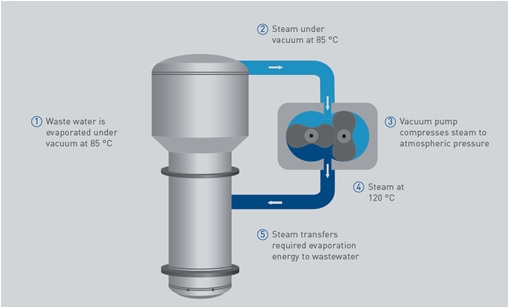

The state-of-the-art technology is based on the simple principle of separation of materials due to boiling point deviations. The industrial wastewater is evaporated.

All substances having higher boiling points than water stay in the evaporation residue. This includes heavy metals, salts as well as oils, fats and tensides. Because the clean water evaporates, the evaporation residue volume is reduced to anywhere between 0.5 and 5 per cent of the original wastewater volume. The emerging vapour is practically free of impurities. After condensation it can be used as process water in the production process. This creates a complete zero liquid discharge production. Industrial wastewater is often heavily polluted with oil, fat and heavy metal salts. It is not allowed to be disposed of into the public sewer system without treatment.

Some substances cannot be completely separated by this principle. Thus the distillate of conventional evaporators is often turbid and of poor quality, requiring post treatment.

VACUDEST has introduced many innovations, setting market benchmarks for optimising the separation process. The VACUDEST process guarantees crystal clear distillate with outstanding quality when compared to other conventional evaporators.

The Clearcat condensation system allows COD reduction (COD: Chemical oxygen demand, a measurement for the degree of pollution with organic substances) of up to 99 percent.

Your investment in a VACUDEST vacuum distillation system from Lancy Technology is your guarantee of excellent distillate quality.